Manufacturing Audits

Manufacturing and Production Audit

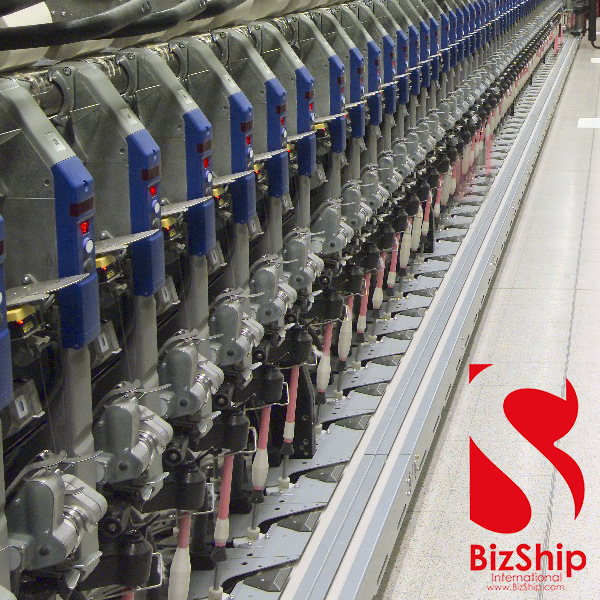

To know the exact status of suppliers and their capability to produce the required products of given quality in specific time, these audits help our client to make a timely decision and manage their supply chain more effectively. Production and Manufacturing audits are conducted by our qualified auditors for textile factories, towel factories, garments and apparel factories, denim factories, and other consumer or industrial product manufacturing factories. Manufacturing Audit Services Manufacturing Audits of Production Facilities & Factories in all sectors including Textiles, Fabrics, Apparels & Garments, Denim, Cotton Bags, Towels, Kitchen Textiles, Food Products, Consumer Products, Electronic Products, Electrical and Construction Products.

Manufacturing Audits & Quality Conference

Manufacturing Audits ensure the process quality of manufacturing & assembling of products or parts. Multiple manufacturing audits may be needed for the complex products of high quality. Manufacturing audits are conducted for textiles, garments, towels and allied industries along with industrial, consumer, pharmaceutical, food and consumer products.

BizShip manufacturing audits help you reduce your production and procurement cost and makes your supply chain more effective and time focused.

BizShip manufacturing audits comply with international quality, work and environment standards including ISO 9000. Qualified, experienced, professional and highly vigilant auditors of BizShip auditors’ team check each and every aspect required to be considered during specific audit visits and their reports. BizShip suppliers’ manufacturing audits include:

- Entire Factory Profiling

- Conference of prevailing Quality Systems

- Confirmation of Production Capabilities and Quality Standards

- Process flow and Production Workflows of the Supplier

- The physical condition of building, plant, machinery, rest areas, washrooms, eating areas, cooking area, parking, stocks & godowns

Added Value & Customized Audit Programs

Additional value can be added by including extra modules and audit protocol. Added value is required when your concerns are more than merely a factory’s physical condition and you need to know and check suppliers’ adherence and capabilities in the following areas also:

- RoHS Standards and their implications

- Method of Raw Material Procurement

- Storage and Maintenance Function of the Supplying Factory

- Research & Development Function of the Factory

- Sample Production and Quality Testing Lab’s Evaluation

- Environmental influence and Impact

- Client Specific Modules and Sections

Manufacturing Audit Prices

Per Man Day prices of standard manufacturing audit are based on location and distance of suppliers’ facility or factory.

Within Pakistan: $549 / man-day – $349 / per additional man day.

One man day duration is good for small factories with less than 500 workers. For larger suppliers, more days may be required.

Out of Pakistan: $749 / man-day – $549 / per additional man day.

One man day duration is good for small factories with less than 500 workers. For larger suppliers, more days may be required.

BizShip Benefits for you include

- Simple pricing, no additional or personal expenses added later

- No hidden expenses and costs

- No extra taxes other than mentioned (where applicable) in the agreement

- Minimum time in Audit Execution

- Online Support and Reporting on your BizShip account and Email

- Reduced supply chain cost

- Improved quality of the finished product

Order Your Audit Program